The use of aluminium extrusion in product design and manufacturing has increased significantly in recent decades, used by a wide selection of different industries including architecture, automotive, electronics, aerospace, renewable energy, and more.

What is aluminium extrusion?

Aluminium extrusion is a process used to form objects with a fixed cross-sectional profile. It involves forcing aluminium alloy material through a shaped die to produce elongated pieces with a consistent cross-section. After extrusion, the aluminium profile is cooled, stretched and straightened if necessary. It can then undergo additional processes such as cutting, machining, bending, or surface finishing to achieve the desired final product.

Find out more about what makes a good aluminium alloy for bending.

The process of aluminium extrusion

Billet preparation

The extrusion process begins with the preparation of the billet, a solid cylindrical piece of aluminium that is typically made from aluminium alloy and may undergo processes such as homogenisation to ensure uniform composition and structure. It is then heated in a furnace to a specific temperature, typically between 400°C to 500°C (750°F to 930°F) depending on the desired extrusion properties.

Die heating

While the billet is being prepared, the die is also heated to a specific temperature which helps to prevent sudden cooling of the aluminium and ensures better flow and more accurate shaping. The die temperature is carefully controlled based on factors such as the alloy being extruded and the complexity of the profile.

Billet loading

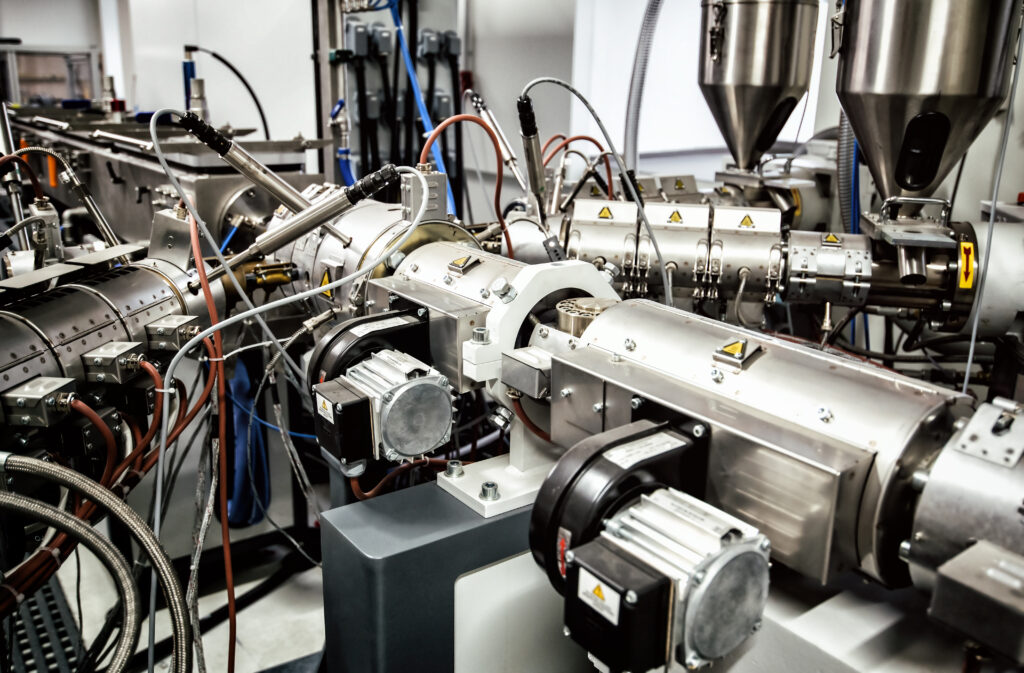

Once the billet and die are suitably heated, the billet is loaded into the extrusion press. The press is a large hydraulic or mechanical machine capable of exerting tremendous pressure to push the softened aluminium through the die.

Extrusion

The extrusion process begins with the press exerting force on the heated billet, pushing it through the opening. As the aluminium passes through the die, it takes on the profile of the die opening, forming a continuous length of aluminium with a fixed cross-sectional shape. The speed and pressure applied during extrusion are carefully controlled to achieve the desired dimensions and surface finish of the profile.

Cooling

As the aluminium exits the die, it begins to cool and solidify. Depending on the alloy and extrusion parameters, cooling may occur naturally or be assisted by water or air cooling systems. Proper cooling is essential to prevent the deformation or cracking of the extrusion.

Stretching and straightening

After cooling, the extrusion may undergo additional processes to improve its straightness and mechanical properties. This may involve stretching the extrusion to remove any residual stresses and straightening it using specialised equipment. These steps help to ensure that the extrusion meets tight dimensional tolerances and surface flatness.

Cutting

Once the extrusion has been straightened and stretched if necessary, it is cut to the desired length using saws or other similar equipment. Precision cutting ensures that each extrusion meets the specified length requirements and is ready for further processing or assembly.

Ageing

As an optional step, some aluminium alloys undergo a heat treatment process known as ageing to further improve their mechanical properties. Ageing involves heating the extrusions to a specific temperature for a predetermined period, followed by controlled cooling. This process can enhance the strength, hardness, and stability of the aluminium.

Surface treatment

Depending on the intended application and aesthetic of the final product, the extrusion may undergo surface treatments such as painting or powder coating. These treatments provide additional protection against corrosion, enhance the appearance and improve durability.

Quality control

Throughout the extrusion process, quality control measures are implemented to ensure that the finished object meets specific requirements and standards. This process includes visual inspections, final measurements, mechanical testing, and chemical analysis. Quality control ensures that any defects or deviations are detected and any amendments can be made.

Aluminium extrusion bending services provided by ABS

ABS are the UK’s leading company in aluminium extrusion bending. With years of experience, we’re round to be a part of British manufacturing history. With this comes the quality of an ISO 9001 Certificate so that you can be sure we’re able to offer precision manufacturing all of the time.

Whether you need something for an exterior project or bespoke aluminium furniture for the inside, call our team today on 01623 259173 or fill in our contact form for a free quote from ABS.